A cylindrical specimen of a cold-worked brass has a ductility – In the realm of material science, the ductility of cold-worked brass cylindrical specimens holds immense significance. This comprehensive analysis delves into the mechanical properties and microstructure of cold-worked brass, examining the factors that influence its ductility. By exploring the geometry of cylindrical specimens and the various testing methods employed, we unravel the intricate relationship between material characteristics and mechanical performance.

The subsequent paragraphs delve into the mechanical properties of cold-worked brass, the concept of ductility and its measurement techniques, and the impact of specimen geometry on ductility. We also explore the different testing methods used to assess ductility, discussing their advantages and limitations.

Finally, we highlight the practical applications of cold-worked brass, showcasing how its ductility contributes to its suitability for various industrial applications.

Material Properties: A Cylindrical Specimen Of A Cold-worked Brass Has A Ductility

Cold-worked brass is a type of brass that has been subjected to plastic deformation at room temperature. This process increases the strength and hardness of the material, but decreases its ductility. The microstructure of cold-worked brass is characterized by elongated grains and a high dislocation density.

Ductility

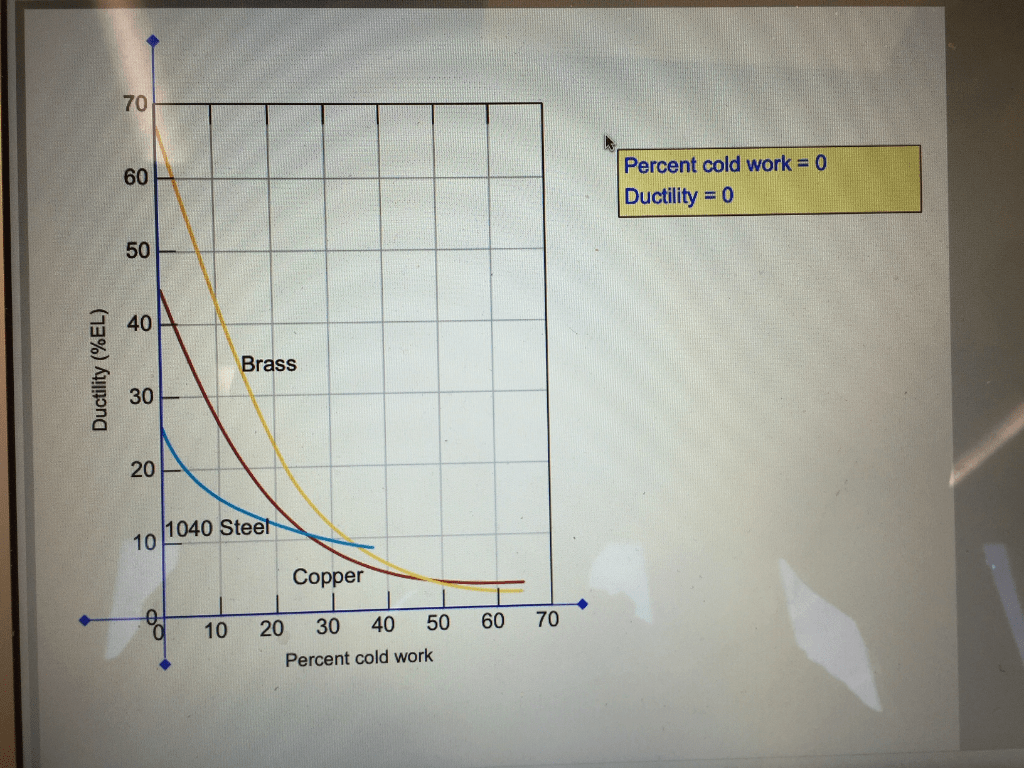

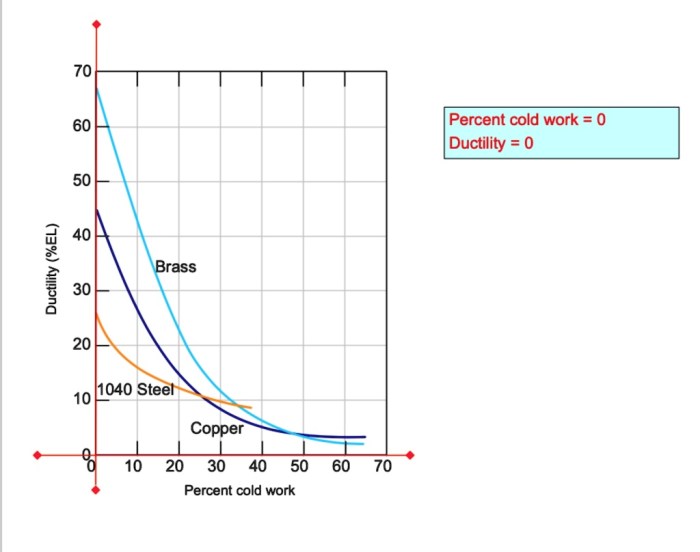

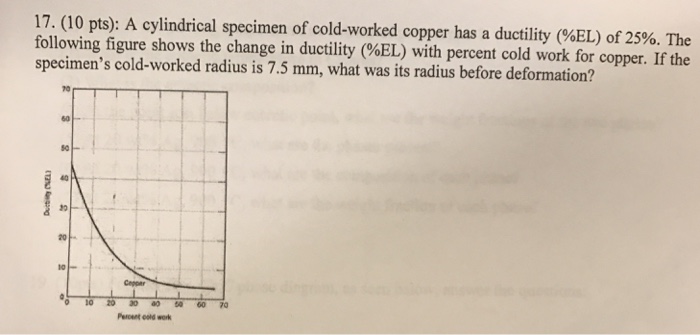

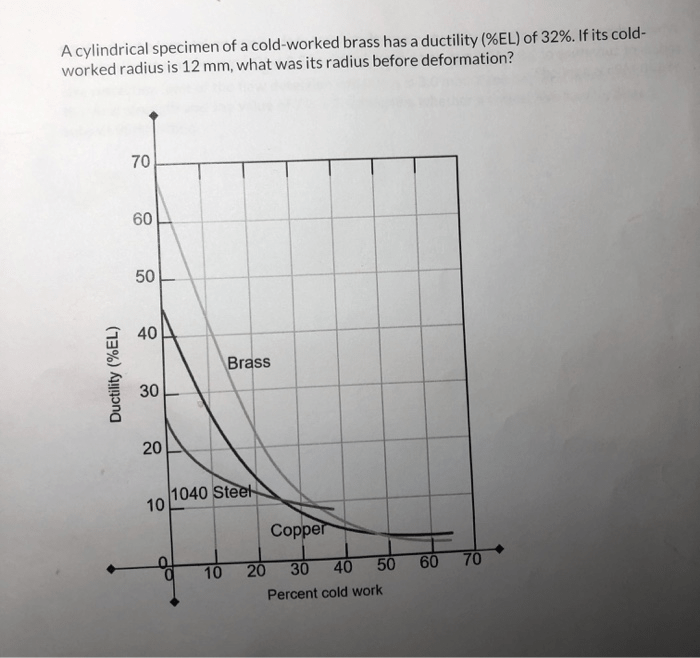

Ductility is a measure of a material’s ability to deform plastically without fracturing. It is typically measured by the percentage elongation of a specimen before it breaks. The ductility of cold-worked brass is lower than that of annealed brass, due to the increased dislocation density and grain elongation.

The ductility of brass is affected by a number of factors, including the composition of the alloy, the grain size, and the amount of cold work. In general, the higher the zinc content, the lower the ductility. The smaller the grain size, the higher the ductility.

And the greater the amount of cold work, the lower the ductility.

Specimen Geometry, A cylindrical specimen of a cold-worked brass has a ductility

The geometry of a cylindrical specimen affects its ductility. The diameter and length of the specimen should be chosen to ensure that the specimen fails in a uniaxial tension test. The ends of the specimen should be flat and parallel to each other, and the surface of the specimen should be free of scratches or other defects.

Testing Methods

There are a number of different methods that can be used to test the ductility of brass. The most common method is the uniaxial tension test. In this test, a specimen is pulled until it breaks, and the percentage elongation is measured.

Other methods for testing ductility include the bend test, the Erichsen cupping test, and the hole expansion test. These tests measure different aspects of ductility, and the choice of test method depends on the specific application.

Applications

Cold-worked brass is used in a variety of applications, including:

- Springs

- Wire

- Musical instruments

- Jewelry

- Automotive parts

The ductility of cold-worked brass makes it suitable for these applications, as it can be easily formed into complex shapes without breaking.

FAQ Compilation

What is the significance of ductility in cold-worked brass?

Ductility is a crucial property that enables cold-worked brass to withstand plastic deformation without fracturing. This characteristic makes it suitable for applications requiring formability and resistance to cracking.

How does cold working affect the microstructure of brass?

Cold working introduces dislocations and defects into the crystal structure of brass, resulting in increased strength and hardness. However, it also reduces ductility due to the reduced mobility of grain boundaries.

What are the key factors that influence the ductility of cold-worked brass cylindrical specimens?

The ductility of cold-worked brass cylindrical specimens is influenced by factors such as the degree of cold work, grain size, and the presence of impurities or defects.